One-step Automatic Strapping Machine WBK450

Automatic Strapping Machine/ Bundling Machine/ PE Film Bundling Machine. Linear feeding and discharging, less mechanical action, low failure rate, simple and clear. The machine is mainly used in packaging and bundling of box-packed products in food and pharmaceutical medicine box industries.

Email: [email protected]

Product detail

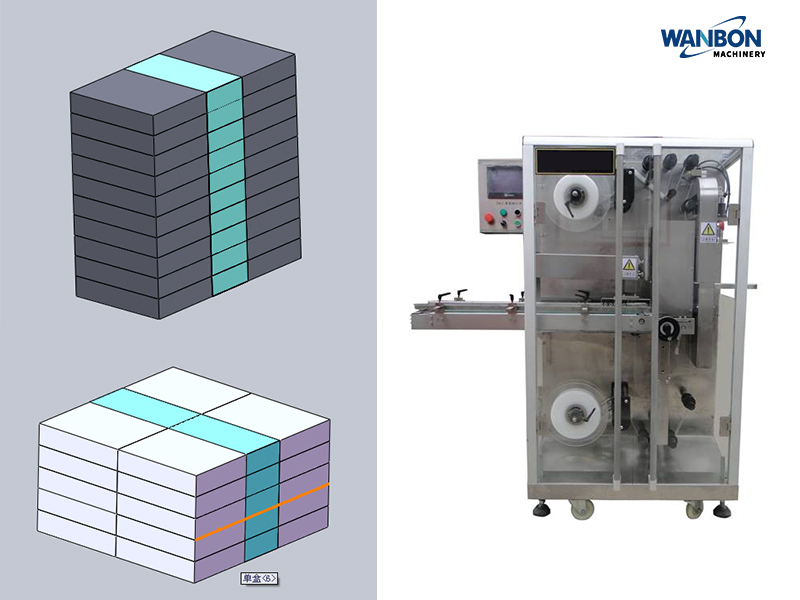

One-step Automatic Strapping Machine WBK450

Automatic Banding Machine Working Process

Production process: conveying → box-erecting → separate feed → press → bundling

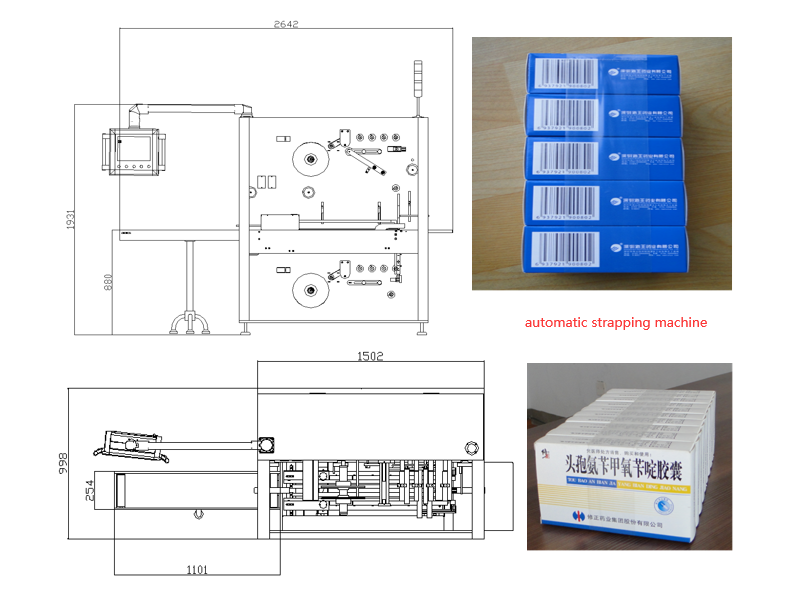

One-step Automatic Strapping Machine WBK450 Main Parametes

| Packing material specification | PE |

| Thickness | 40-90um |

| Width | 30-80mm |

| Max. outer diameter | D=Φ300 mm |

| Paper core aperture | D=Φ76 mm |

| Box specification | |

| Single box package size: LxWxH | 70-180 x 18-40 x 40-90 mm |

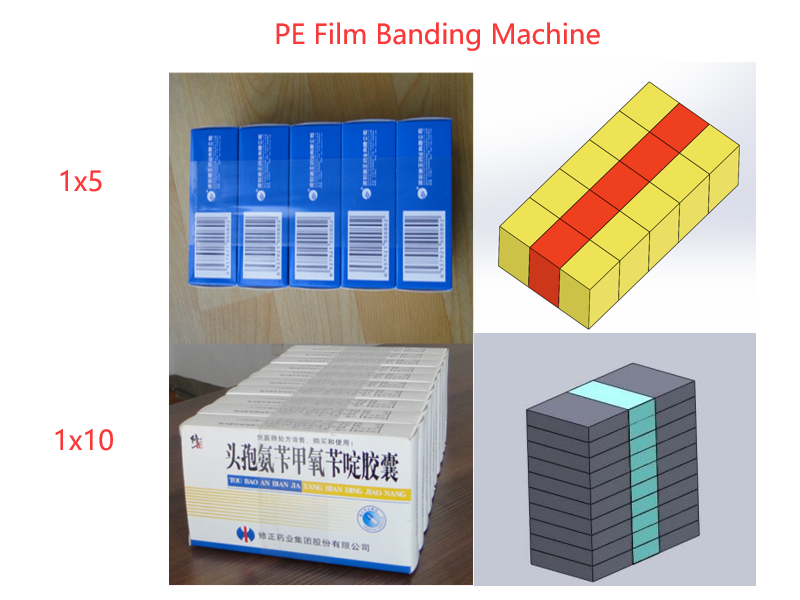

| Packing style | 1×5/ 1×10 /other |

| Machine specification | |

| Packing speed | 35-45 packs/min |

| Power | 220v50hz 2kw |

| Air source pressure | 0.5-0.7Mpa |

| Cutter temperature | 0-250 ℃ |

| Machine dimension | 2640*998*1931mm |

Automatic Strapping Machine/ Bundling Machine/ Banding Machine Main Features

Linear feeding and discharging, less mechanical action, low failure rate, simple and clear.

1.Adopts advanced heat sealing and cutting technology, with stable sealing quality and long service life of cutter.

2.No film alarm and double film rollers to achieve automatic film-catching to improve the working efficiency.

3.The conveyor adopts electronic speed control motor, which can ensure the matching speed with the front equipment cartoning machine.

4.The sealing and cutting cutter adopts unique shape welding. The latest technological innovation, so sealing and cutting is more stable and firm.

5.Replace high-temperature tape with sealed-cut silicone, save consumables than other manufacturers’ machines, for example, if each shift needs to consume one roll high-temperature tape per week, my machine can save 30-50 rolls a year).

6.High-temperature resistant stainless steel tube with good insulation performance is more durable.

7.PLC control, the whole process of automation, Dual servo motors control feeding and sealing & cutting, erecting belt to ensure speed and stability. The bundling part uses automatic photoelectric control, easy to adjust, stable and reliable.

8.Electrical configuration: pneumatic components using SMC products.

The electrical components such as PLC, touch screen, servo motor are from Siemens , transmission, film feeding motor are GPG.

9.Easy to change varieties, touch screen and hand wheel adjustment.

10.Small footprint, the overall length of 2700mm, within conveyor belt 1000mm, according to the site area, connection requirements and other limiting factors to shorten or lengthen the feed belt.

Send Inquiry

Copyright © 2026 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish