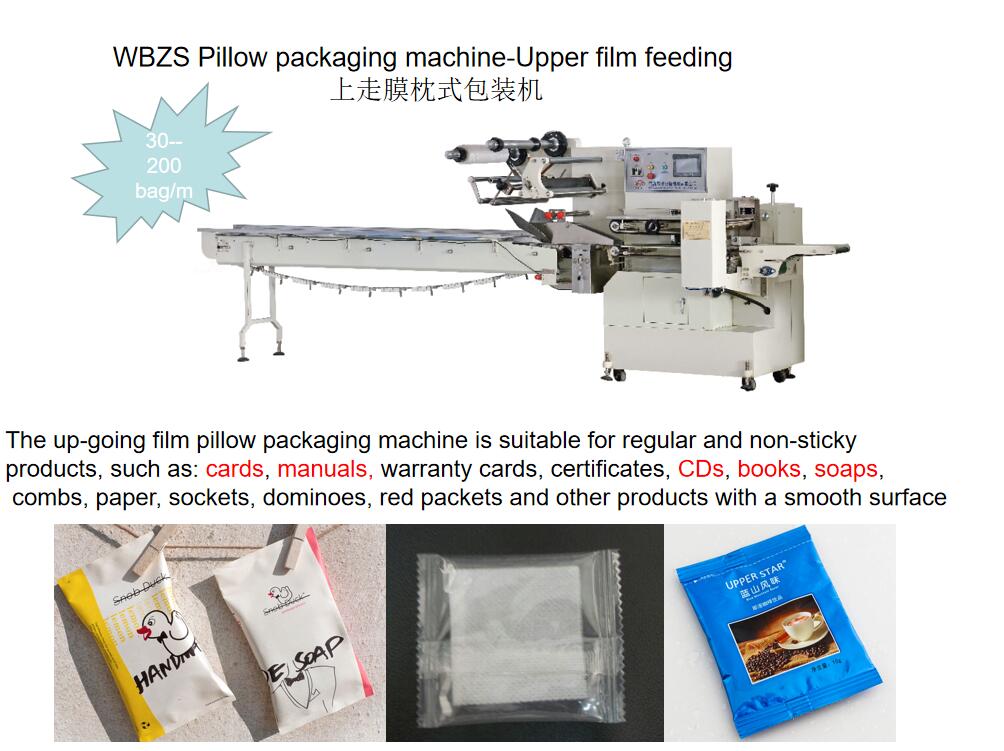

Automatic horizontal flow wrap packing machine for biscuit food

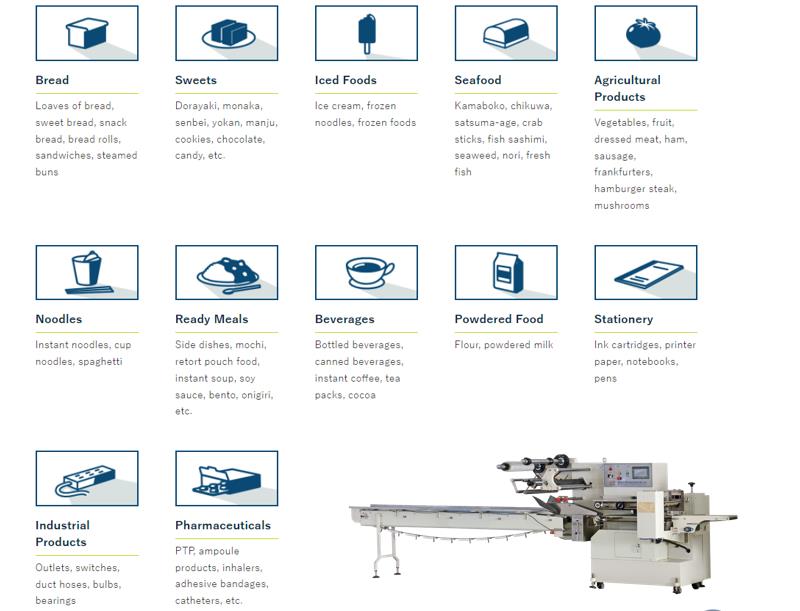

Flow wrap packing machine to pack biscuit,soap,instant noodel,water filter,bread,bakery food and so on. High efficiency pillow packing machine ......

Email: [email protected]

Product detail

Automatic horizontal flow wrap packing machine for biscuit food

Flow wrap packing machine to pack biscuit,soap,instant noodel,water filter,bread,bakery food and so on.

High efficiency pillow packing machine Product Features:

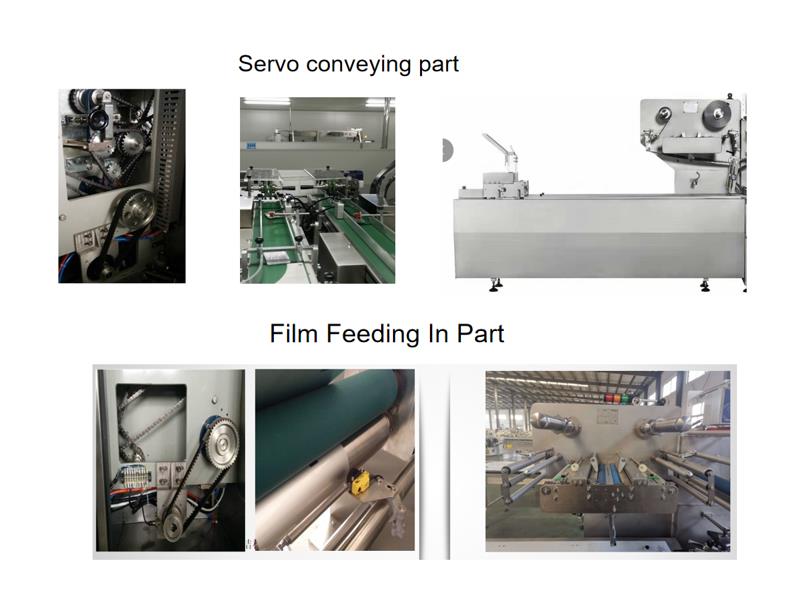

1. The servo system replace the traditional mechanical film feeding system, which simplifies the mechanical structure, making packaging machine run more smoothly. Routine maintenance is more convenient, simple, reducing skill requirements to the operator, machine running noise and error rate are significantly reduced.

2. Host machine adopts frequency control, reducing the cost of the machine and increasing the cost-effective.

3. Digital display can directly display packaging film length, packing speed, output, temperature and other parameters.

4. PLC control can reduce mechanical contact and make the system more stable, reliable, and maintenance easier.

5. Adopting bidirectional automatic tracking and detecting color code by photodetector.

6. The main electrical parts are well-known international brands to ensure the stable operation of equipment.

7. It has a positioning and parking function (prevent iron the film).

The main technical parameters:

| Model | WBZS450-99 | WBZS450-120 | WBZS450-150 | WBZS590-120 | WBZS590-150 | WBZS590-180 |

| Maximum film width(mm) | 430 | 430 | 430 | 570 | 570 | 570 |

| Packing speed | 30-200 | 30-180 | 30-180 | 30-180 | 30-180 | 30-150 |

| Bag length range(mm) | 75-400 | 90-400 | 90-400 | 900-400 | 90-400 | 90-400 |

| Packing width(mm) | 10-140 | 10-150 | 10-150 | 30-200 | 30-200 | 30-200 |

| Packing height(mm) | 5-40 | 15-60 | 30-90 | 15-60 | 10-100 | 40-120 |

| Power supply(V) | 220V 50HZ | 220V 50HZ | 220V 50HZ | 220V 50HZ | 220V 50HZ | 220V 50HZ |

| Total power(KW) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 |

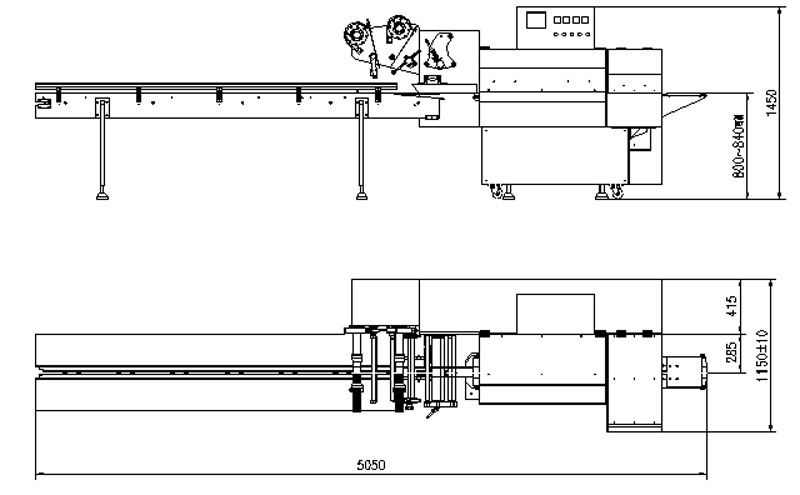

| Dimension((Length*width* height))mm | 5050*960*1600 | 5050*1200*1700 | ||||

| Total weight(kg) | 1000 | 1200 | ||||

Send Inquiry

Copyright © 2026 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish